DongGuan Great Silicone Technology Co.Ltd.

E-mail:info@great-silicone.com

Add: No.15 Room,10 Floor Of RongDa Building,NanCheng District,Dongguan China.

GS-A20 shoe sole mold making platinum cure liquid silicone

GS-A20 shoe sole mold making platinum cure liquid silicone rubber

1.Description of shoe sole mold making platinum cure silicone rubber

GS-A20 Silicone rubber is platinum cure silicone rubber for mold making and silicone products. The silicone rubber will be cured under room temperature and can be cured fastly by heating, It’s two-components liquid silicone rubber , the mixing ratio is 1:1 . It has an exceptional fluidity and good operability.Especially ,the platinum cure silicone rubber has a lower shrinkage less than 0.1 % without deformation,higher temperature resistance .

The important advantage of GS-A20 is the shrinkage is lower less than 0.1 % , so it is the best suitable for complicated product .

2.Characteristics of shoe sole mold making platinum cure silicone rubber

*An exceptional fluidity and good operability

*Good tensile strength and tear strength

*Food grade silicone rubber

*high temperature resistance

*good flexibility

*No smell ,non-toxic

*long shelf-time &lifetime

*Lower shrinkage

3.Application of shoe sole mold making platinum cure silicone rubber

GS-A20 silicone rubber is suitable to make tyre mold and shoe mold ,because of the lower shrinakge .

The difference of GS-C20 and GS-A20 . Both of the two types silicone is suitable for shoe mold and tyre mold , GS-A20 has a lower shrinkage less than 0.1% , so it is best for complicated shoe molds . GS-C20 has a shrinkage less than 0.3 % , it is suitable for simple molds , but it is much cheaper than GS-A20.

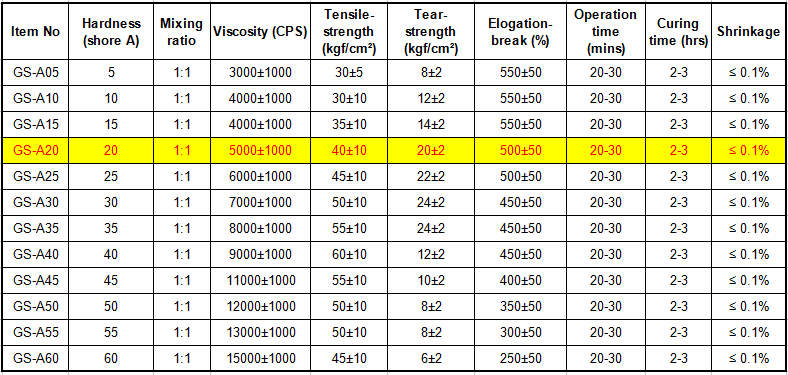

4.Datesheet of shoe sole mold making platinum cure silicone rubber

5.Operating instructions of shoe sole mold making platinum cure silicone rubber

Step 1: prepare and clean the prototype.

You must make sure your original molds perfect. fix the original mold on a board , then using some assistant material(like cardpaper) to make a frame for to surround the prototype. The frame is no need ,if we make the mold by brushing way .

Step 2: Take the silicone and catalyst as the ratio1:1 (part A:part B=1:1) ,mix the silicone rubber and catalyst evenly.

*Notes: Molding silicon rubber is a kind of flowing liquid and it contains two parts. Remember to mix part A and part B evenly, otherwise the silicon rubber will be partly solidified and this will bring troubles for your final operation. What’s more, the finished molds will have a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping

After mixed the silicone evenly, it is better to release the bubble by Vacuum pumping.

Step 4: Pouring cast or brushing cast

After released the bubble, we can pour/brush the silicone rubber on the prototype

*Notes:Please finished all the steped within the operation time .If not it will cause cross linking reaction, and no more further steps will be available.So,we have to pay attention to the pot life and curing time.

Notice of platinum cure silicone rubber of shoe sole mold making platinum cure silicone rubber

GS-A20 is platinum cure silicone , which is very easy to cause cure inhibition , so please do remember thoroughly clean the model and tool before operation . Besides , please avoid the condensation silicone rubber (100:2) contact or mix with the following material , otherwise the silicone won’t be cured :

1. Liquid condensation silicone ( condensation silicone not completely cured or organic tin compounds )

2. Sulphur, sulfide and sulfur rubber materials.

3. Amine compounds as well as contains the amine materials.

4. impurity, organic tin catalyst, acid, alkaline and other organisms containing sulfur, phosphorus and nitrogen will influence the vulcanization of the silicon rubber

6. Package and shelf life of shoe sole mold making platinum cure silicone rubber

Package

1kg/drum,5kgs/drum,20kgs/drum,25kgs/drum,200kgs/drum.

Shelf life and transportation

1. Twelve(12) months when stored at 25C in tightly closed original packages.

2. This kind of product is non-dangerous product, which could be transported as general chemicals.

Any questions, pls feel free to contact us , it will be our great pleasure at service for you:

E-mail: sarah@great-silicone.com

Mobile: 0086-18565639690

Whatsapp: 0086-18565639690