Great-Silicone Technology Co.,Limited

Mob:0086-18682484160

Skype: allen.jou1

E-mail:info@great-silicone.com

Add:Longgang district,shenzhen city,in China

GS-C25gypsum cornice molding liquid silicone rubber

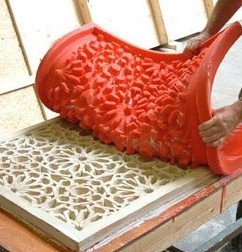

GS-C25 liquid silicone rubber for gypsum cornice , panel ,pillar molding with small and middle size by pouring

GS-C25 is condensation silicone rubber. It is two component ,flexible &softer . It can be used to make mold for gypsum mould ,plaster mould ,resin mold ,sculpture mold ,etc... It has a good flowability, it is better to make mould by pouring .As for the hardness of GC-C25 is just 25 shore A (softer) , it is suitable for small or middle size product , and complicated product.

Feature

1,Flexible and good flowability

2,easy to operation and demould

3,long lifetime

4,High tear&tensile strength

Datasheet:

Item | Appearance | Hardness(shore A°) | Viscosity(CS) | Tensile strength(kgf /cm2) | Tear strength(kgf /cm2 ) |

GS-C25 | White | 25±2 | 18000±2000 | ≥41 | ≥25 |

Elongation-break(%) | Mix ratio | Operation time(25 ℃ ) | Curing time (25 ℃ ) | shrinkage(%) | |

≥450 | 100:3 | 30-45 mins | 3~4 h | ≤0.3% |

Operation instuction:

1,weigh the silicone rubber and catalyst with the ratio of 100:3.(If you need to add ur own pigment , pls add the pigment into the silicone as ratio 0.5%)

2,Stiring them evently , then transfer them to the vacuum machine to release the bubble.

3, Pls clean your product before you pour or brush the silione rubber on your product .If your product is very complicated , you can spray some release agent on your product before pour silicone.

4,After 3~4 hours ,the silicone rubber will be dried fully , then you can demould it .

Dear customer , if you have any question or problem about the technique of making mold ,pls feel free to contact us , we will be happy to provide technical supports.